1Apple’s Commitment To Safe Working Conditions In Our Supply Chain | August 2014

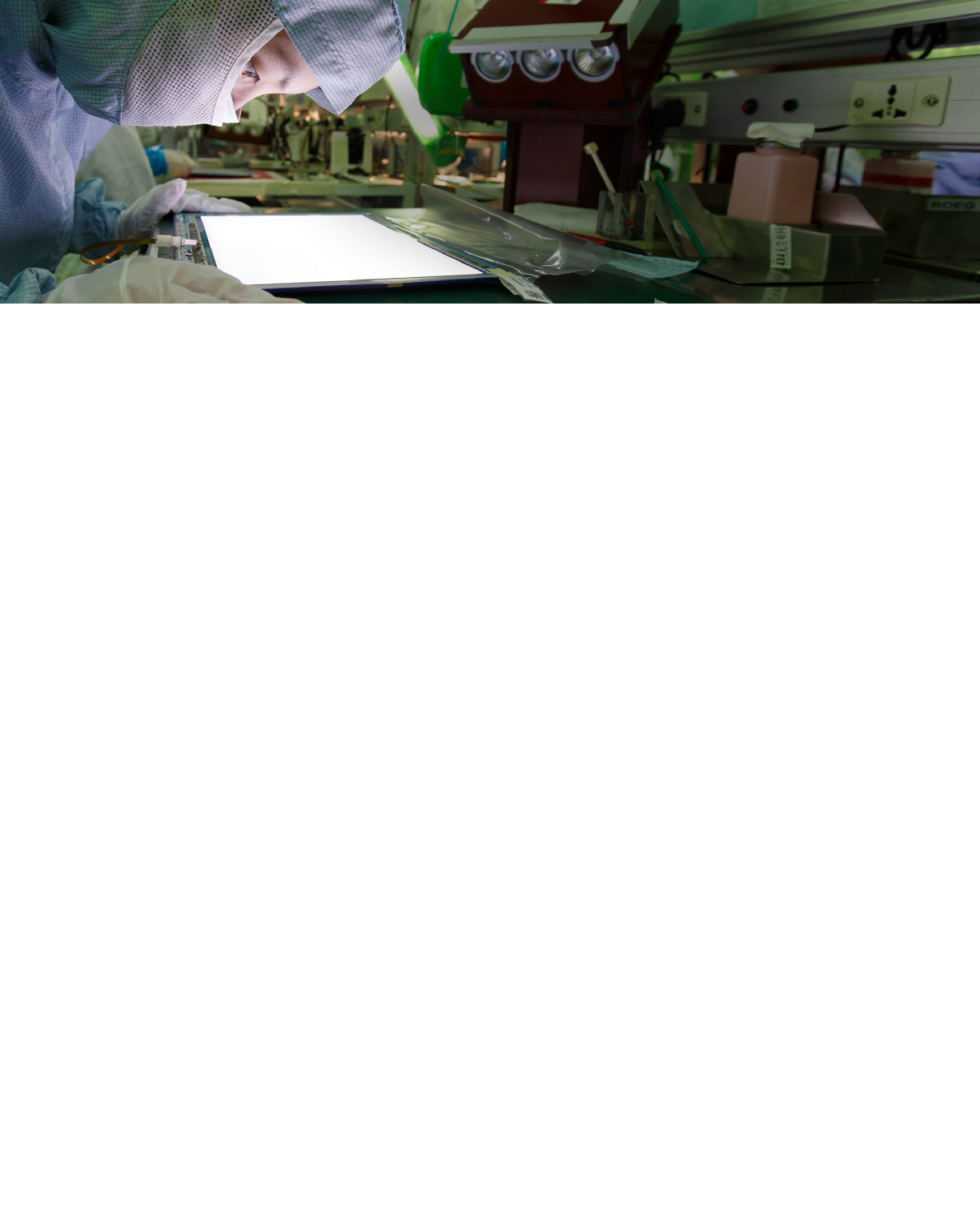

We believe that every person who makes Apple products has the right to a safe and

healthy workspace. Recently we’ve received some questions about whether workers in

our supply chain are being harmed by unsafe exposure to the chemicals benzene and

n-hexane. We want to take this opportunity to address those concerns by explaining

how we investigated them, what we found, and what improvements we’ve made.

Strict standards, rigorous training.

To do business with Apple, our suppliers must follow some of the toughest standards in

the electronics industry. When it comes to handling chemicals and toxic substances, the

standards that we set for our suppliers across the world — regardless of their location

— meet or exceed respected U.S. safety standards such as those set by the National

Institute for Occupational Safety and Health (NIOSH) and the American Conference of

Governmental Industrial Hygienists (ACGIH).

an occupational exposure limit of 0.5 parts per million for benzene, as recommended

by ACGIH, and 28 parts per million for n-hexane, in line with NIOSH. To ensure that sup-

pliers follow our strict requirements, last year we conducted nearly 200 factory inspec-

tions focused on hazardous chemicals — in addition to the 451 general supplier audits

we completed.

We also provide extensive training. Through our 18-month Apple Supplier EHS

Academy, we instruct the environmental health and safety managers in our supplier

facilities in best practices that include hazardous chemical management, industrial

hygiene and personal protective equipment. This program is raising the bar for EHS

across our supply chain, and we’ve been encouraged by how our suppliers have

embraced the opportunity.

Digging deep.

Still, we know we can do better. No one is tougher on Apple than we are on ourselves,

and we’re constantly pushing ourselves to improve. So we decided to do a focused

evaluation of benzene and n-hexane.

Benzene and n-hexane are ingredients in many substances, such as paint strippers,

industrial cleaning products, and household cleaners. As common as these chemicals

are, we decided not to exclude any use in our search; we set out to catalog every use

-

mon manufacturing processes and collectively employ nearly 500,000 people.

Apple’s Commitment To Safe

Working Conditions In Our

Supply Chain

2Apple’s Commitment To Safe Working Conditions In Our Supply Chain | August 2014

Over the course of four months, our specially trained teams made visits to these 22

sites. Our experts:

• reviewed the Material Safety Data Sheets (MSDSs) provided by the manufacturer of

sent the chemical for third-party testing

• screened chemical mixtures for benzene or n-hexane

• re-evaluated personal protective equipment uses

•

• re-reviewed industrial hygiene monitoring reports and the worker medical records

that we require suppliers to keep in order to discover any health changes

use of benzene or n-hexane, and no evidence of worker health and safety being put

at risk from exposure to the chemicals. In the few cases where we found our suppli-

ers using cleaners or substances that did contain benzene or n-hexane, it was in low

In 18 of the 22 facilities, we found no evidence of benzene or n-hexane at all.

found some substances that contained benzene or n-hexane within our RSS limits. To

maintain manufacturing equipment, one facility was using two cleaning products that

didn’t list benzene or n-hexane in the MSDS provided by the manufacturer, but when

replacements. Another facility was using a small amount of n-hexane in a chemistry

laboratory, under a fume hood and with all the proper safety precautions in place. The

third facility was using a cleaner that contained n-hexane, and they have switched to

an alternative.

In the last facility, an accessory supplier, four substances that were being used in the

not listed in the MSDSs, and each use was within the limits of our RSS. Nevertheless,

Next steps

things from our investigation. First, we concluded that safer alternatives to these

chemicals exist. So we have updated our RSS to explicitly prohibit the use of benzene

also tightened our benzene restriction even further, to 0.1 ppm from 0.5 ppm.

We also know that it’s important to double-check the list of ingredients provided by

the manufacturers for chemicals used in our supply chain. In order to address any

We’re going to keep extending our work deeper into our supply chain, pushing our-

selves to minimize harmful toxins, and work with stakeholders to ensure the health

and safety of everyone who make Apple products.